Schedule a demo

Easy to set up and also comes with advanced functionality to handle complex scenarios.

Integrate SOLIDWORKS, SOLIDWORKS PDM with Dynamics Business Central, Dynamics Navision using PDM2NAV integration

- Automatic transfer of data from SOLIDWORKS PDM to Dynamic navision or Business Central

- Data can be transferred by right click option or by button click or during workflow approval process

- Data can be obtained from Dynamics Navision and presented in SOLIDWORKS PDM

- Compare SOLIDWORKS PDM Bill of Materials ( BOM ) with Dynamics Navision BOM

- Advanced data modification using custom script before sending data to Dynamics Navision or Business Central

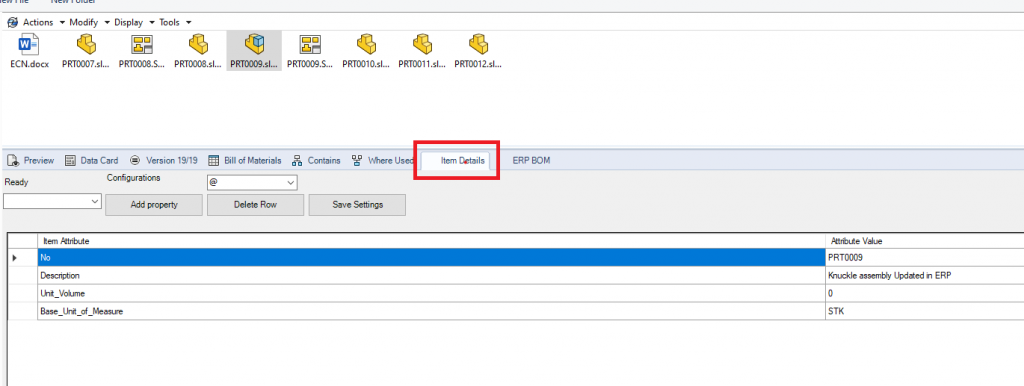

- See Item information in a tab in SOLIDWORKS PDM

- See ERP BOM information in a tab inside SOLIDWORKS PDM

- Compare PDM BOM with Dynamics BOM. It is possible to compare PDM BOM with old version of Dynamics BOM if Production BOMs are being used

- Possible to create Production BOM or Assembly BOM in Dynamics Navision or Business Central

- Documents with multiple configurations are also supported

- Keep track of data transfer between PDM and ERP using our PDM2ERP reporting tool

- SOLIDWORKS add-in to do data transfer activities directly from SOLIDWORKS

- Supports creation of Sales orders, Purchase orders, Sales quotes, Purchase quotes, Sales invoices, and Purchase invoices directly from SOLIDWORKS or PDM

- Supports creation of attachments to Items, and other Sales and Purchase entities

- View or update Customer or Vendor information directly from SOLIDWORKS or PDM without needing to go Business Central

By providing automatic integration engineers need not worry about creation of Items and BOMs in ERP. Instead they can concentrate on design activities

REDUCE THE TIME OF DATA TRANSFERImprove Productivity

Using automatic integration ensures that unforced errors are eliminated

REDUCE COSTS INVOLVED IN RE-WORKEliminate unforced errors

03

By making items available in ERP quickly time to market is reduced drastically

INCREASE SALES

03

Reduce time to market

- Preview Dynamics Navision (Dynamics Business Central) item properties inside SOLIDWORKS PDM.

- Data seen is real-time ERP data

- This also helps to identify if an item exists in Dynamics Business Central or Dynamics Navision

- Item properties that one wants to see in SOLIDWORKS preview can be modified based on the requirement

- Preview settings can be saved so that one need not adjust the properties one wants to see every time

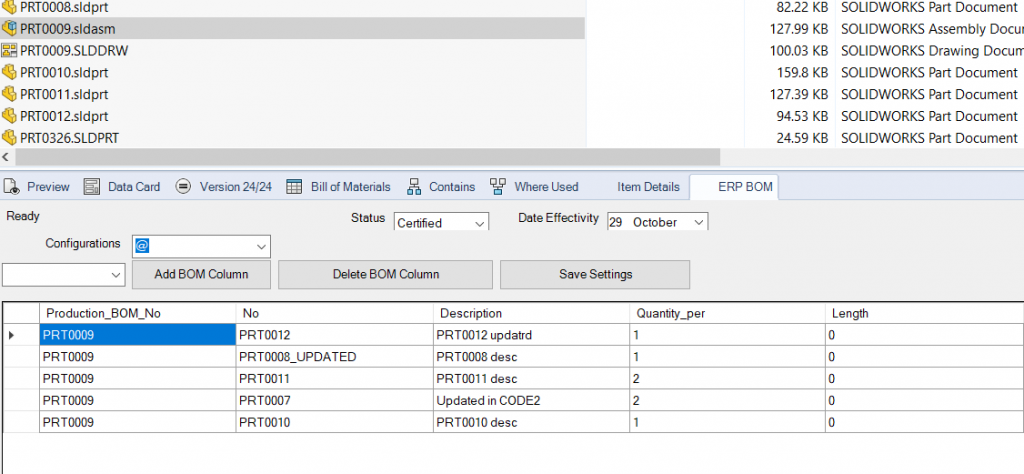

- Preview Dynamics Navision (Dynamics Business Central) BOM inside SOLIDWORKS PDM

- It is possible to preview old Bill of Materials also if BOM versions are being used in Navision or Business Central

- It is possible to choose configurations also if configurations are being used

- It is possible to modify what ERP BOM columns one wants to see inside the PDM preview

- Column settings can be saved for future use

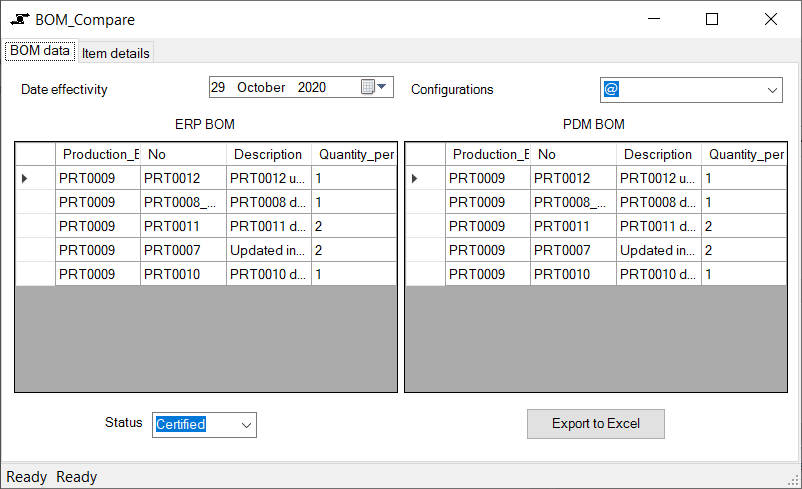

- Compare Dynamics NAV (Dynamics Business Central) BOM with SOLIDWORKS PDM BOM

- It is possible to compare PDM BOM with old ERP BOM if BOM versions are being used in Dynamics Navision or Business Central

- Comparison also shows differences in item properties of first level children.

- This functionality is very useful when one wants to see what changes have been done in PDM since data has been sent last to ERP

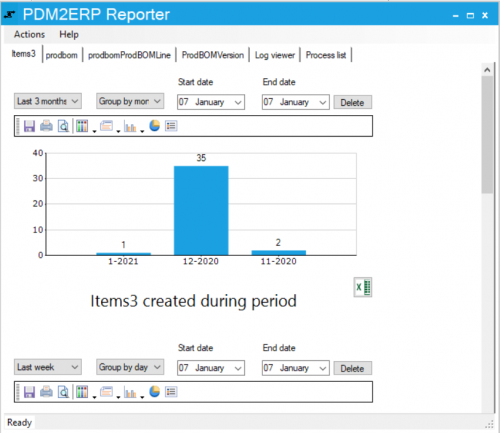

- Using the PDM2ERP tool it is possible to keep track of data transferred to ERP from PDM

- It is possible to see how many items have been created or updated during a period of time

- It is possible to see which user has created or updated how many items during a period of time

- Exports reports to excel for further analysis

- Inside the log viewer, it is possible to see old logs for error analysis

- Inside the process list one can see details of old processes

Schedule a demo